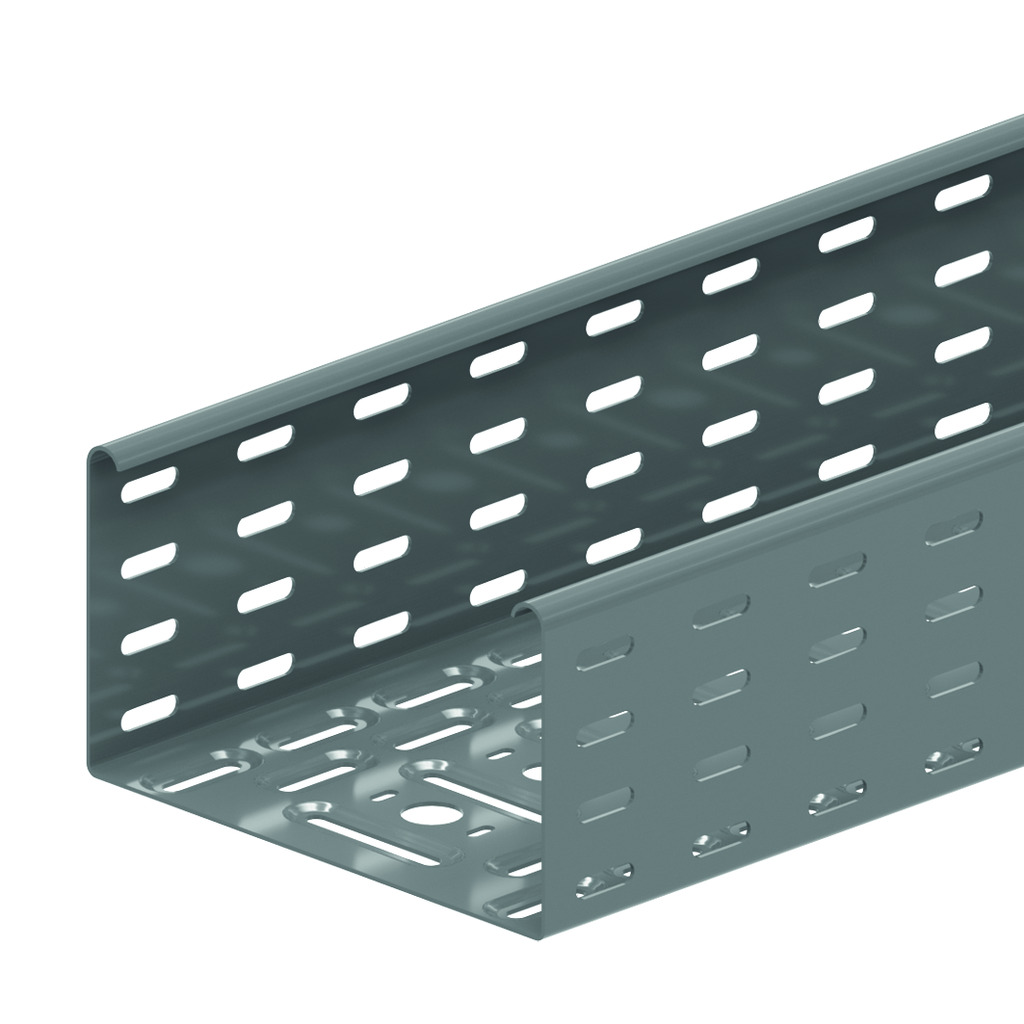

Perforated cable tray - KBS110.6

Alternative perforation

Return flanges

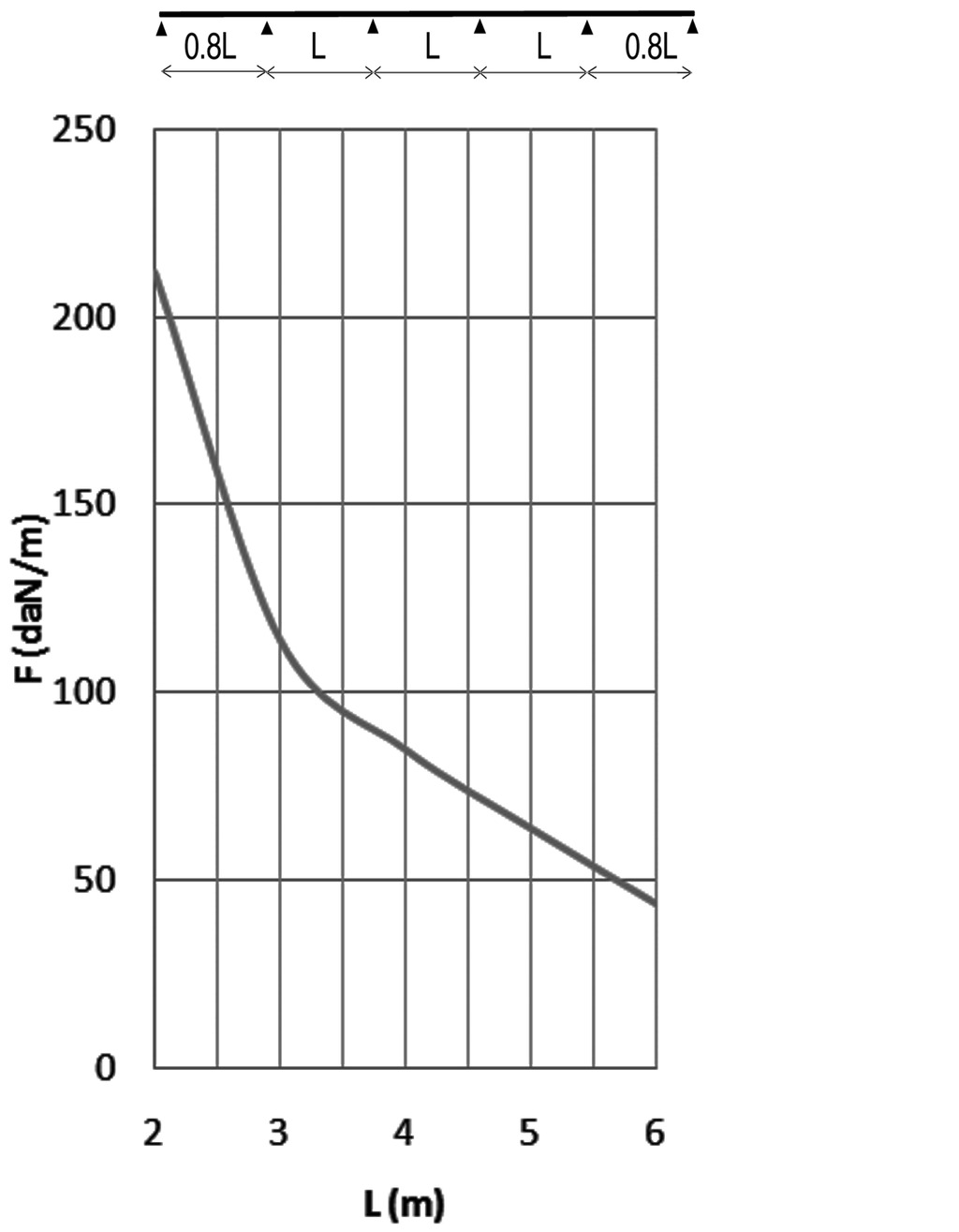

Support distance up to 6 meter

ETIM: EC000047

Return flanges

Support distance up to 6 meter

ETIM: EC000047

| Reference |

mm |

mm |

mm |

mm |

kg m |

Unit | |

| KBS110.200.150.6 | 110 | 200 | 1.5 | 6000 | 4.300 | 24 | M |

| KBS110.300.150.6 | 110 | 300 | 1.5 | 6000 | 5.280 | 24 | M |

| KBS110.400.150.6 | 110 | 400 | 1.5 | 6000 | 6.250 | 24 | M |

| KBS110.500.150.6 | 110 | 500 | 1.5 | 6000 | 7.230 | 24 | M |

| KBS110.600.150.6 | 110 | 600 | 1.5 | 6000 | 8.210 | 24 | M |