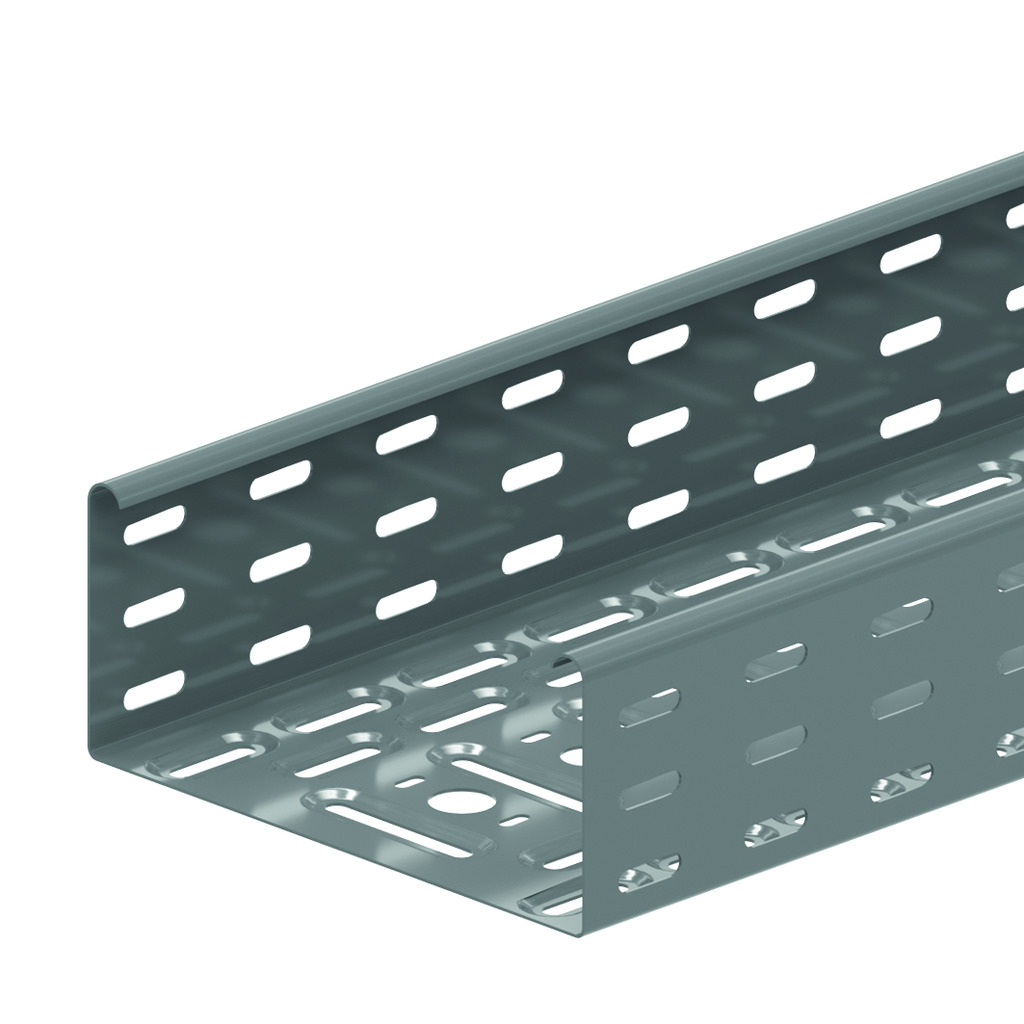

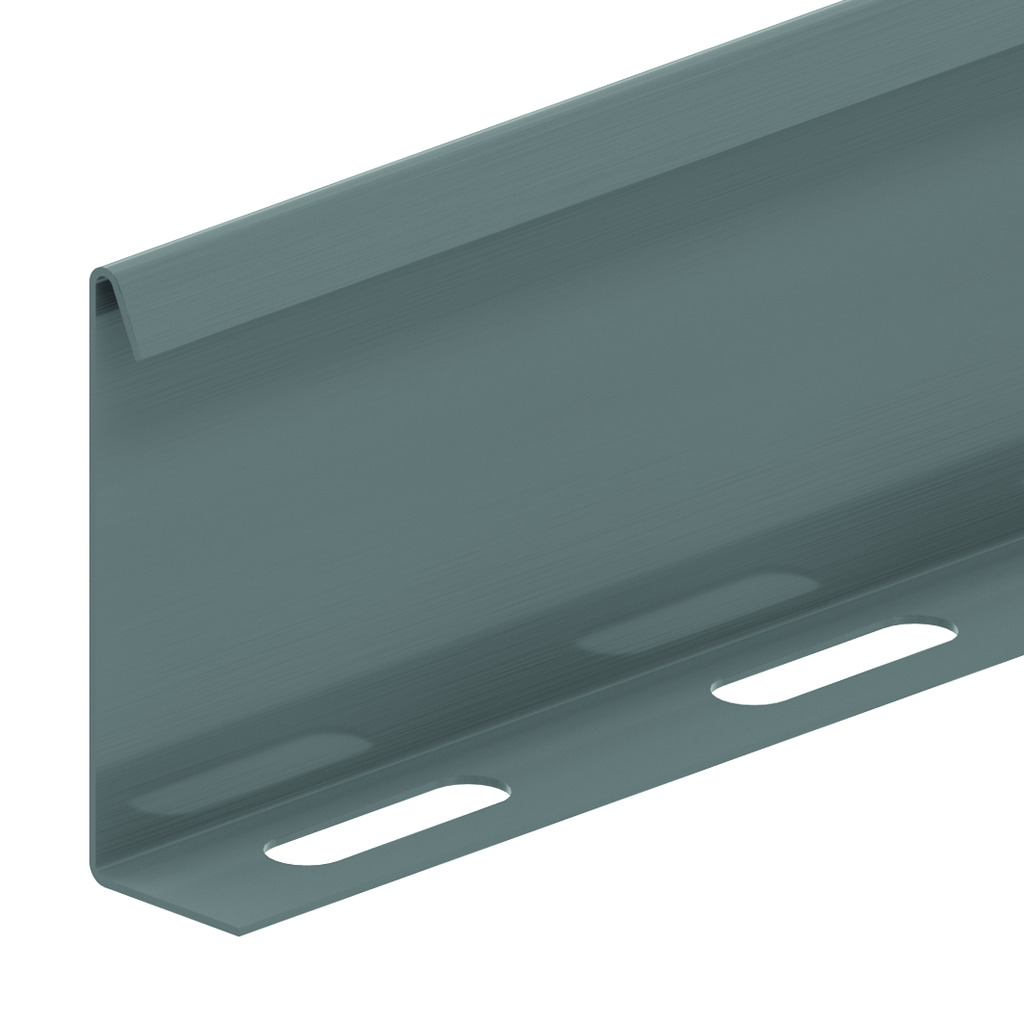

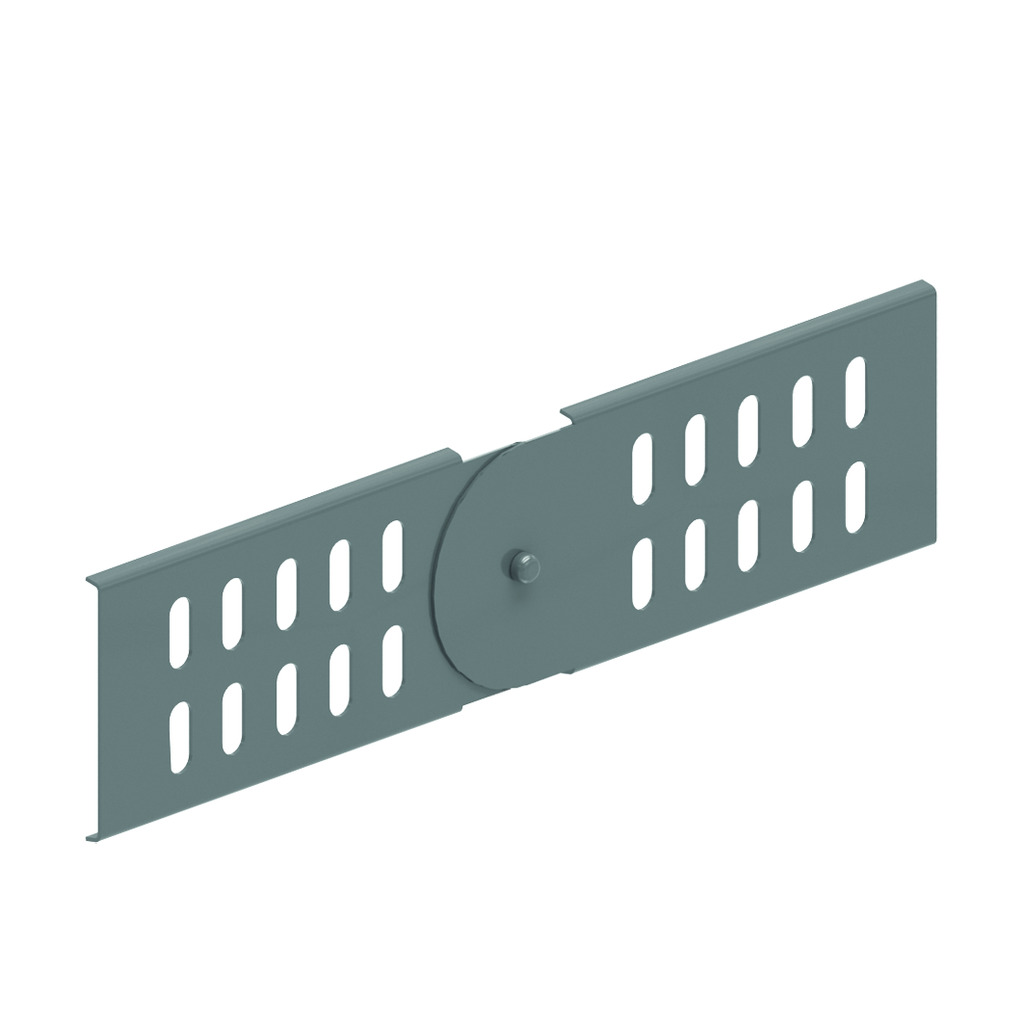

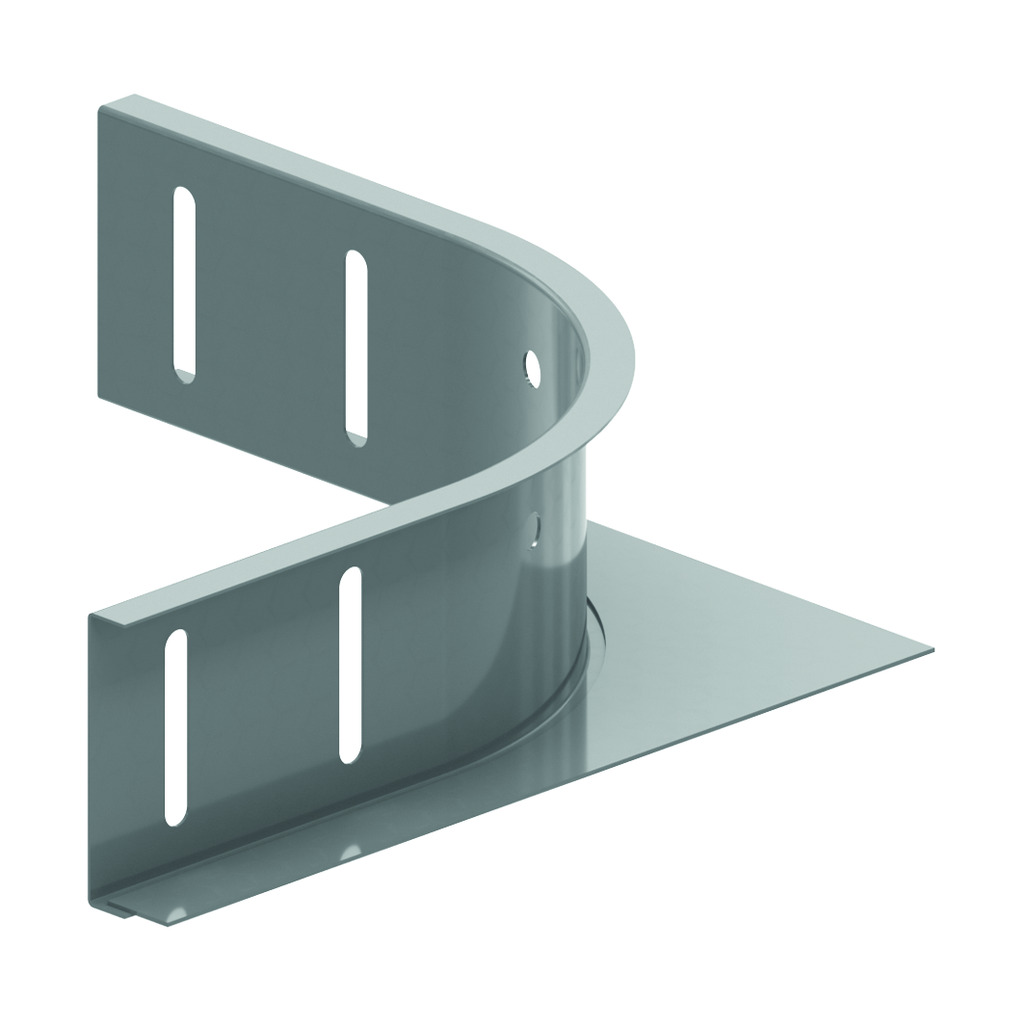

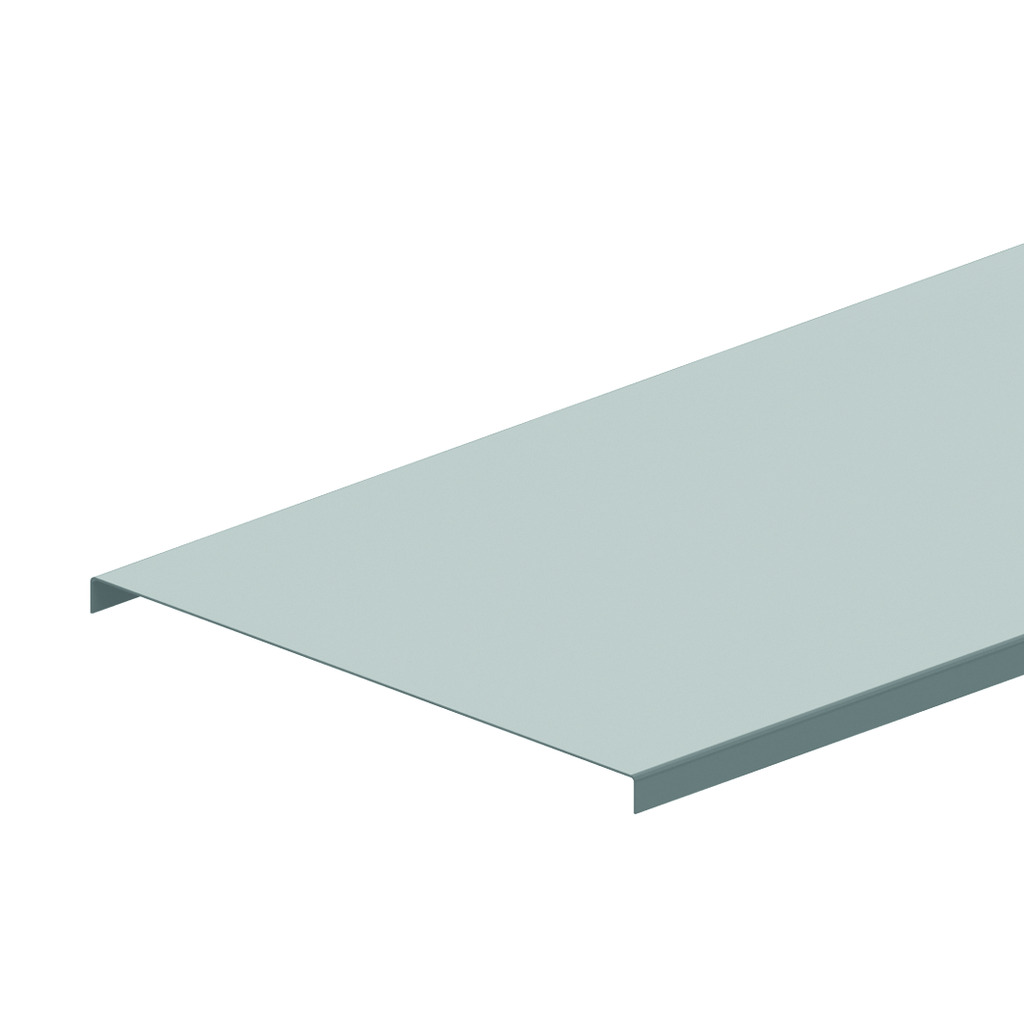

Perforated cable tray - KBS85

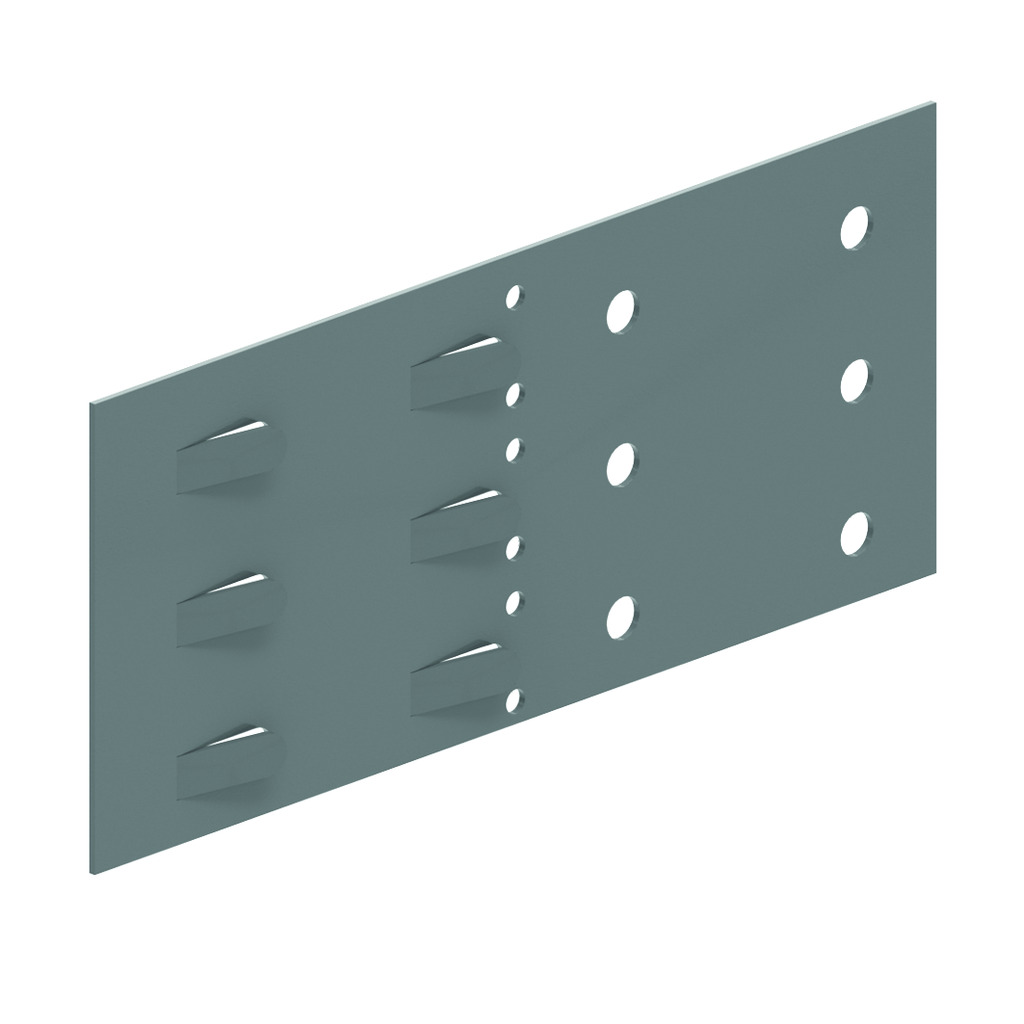

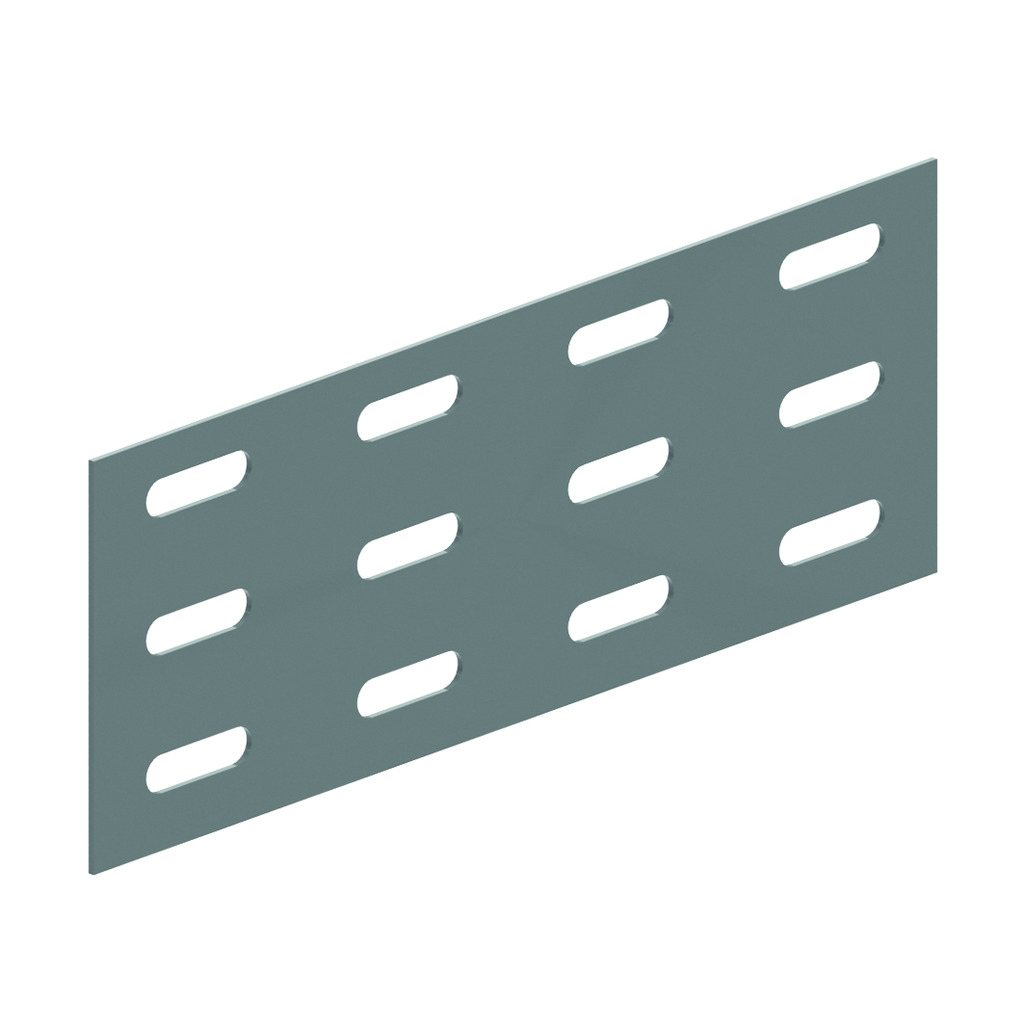

Alternative perforation

Return flanges

ETIM: EC000047

Return flanges

ETIM: EC000047

| Reference | Finish |

mm |

mm |

mm |

mm |

kg m |

Unit | |

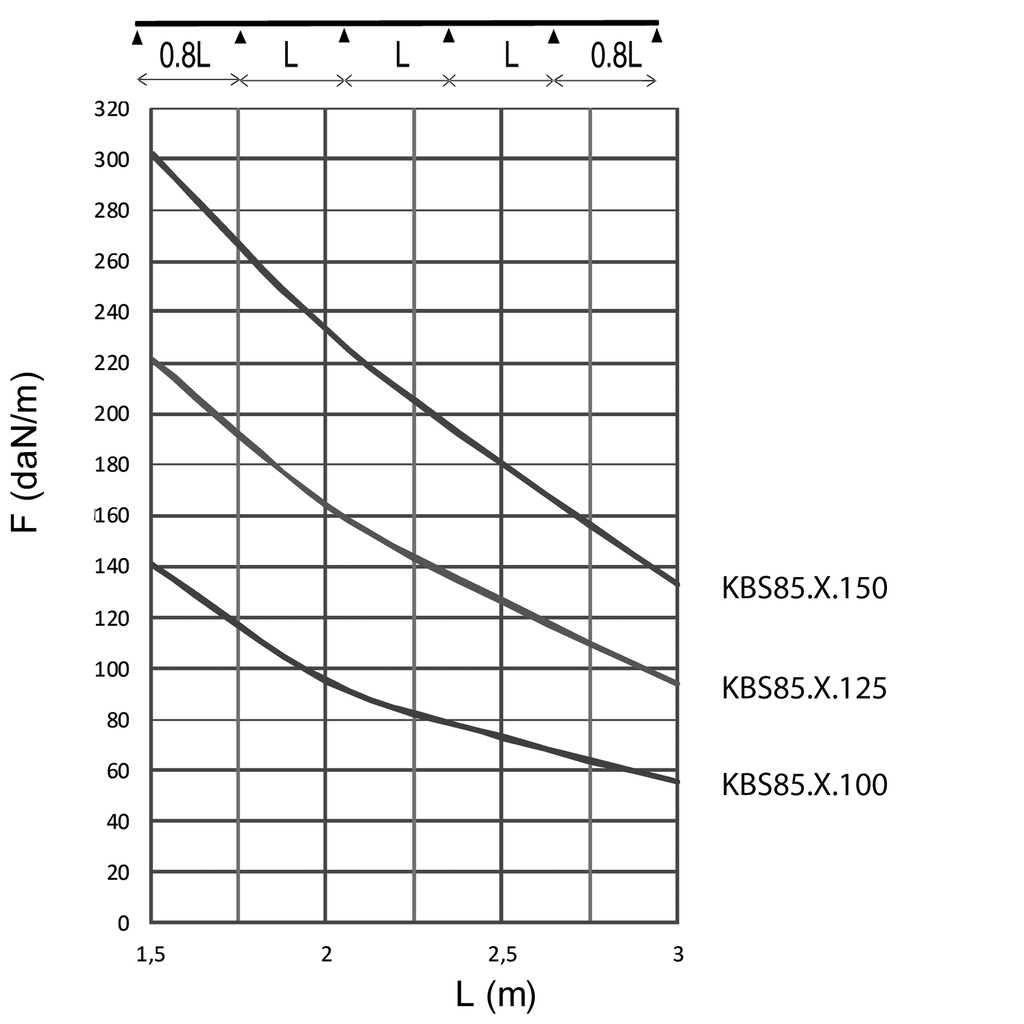

| KBS85.100.100 | SZ | 85 | 100 | 1 | 3000 | 1.890 | 24 | M |

| KBS85.150.100 | SZ | 85 | 150 | 1 | 3000 | 2.220 | 24 | M |

| KBS85.200.100 | SZ | 85 | 200 | 1 | 3000 | 2.540 | 24 | M |

| KBS85.300.100 | SZ | 85 | 300 | 1 | 3000 | 3.190 | 24 | M |

| KBS85.400.100 | SZ | 85 | 400 | 1 | 3000 | 3.840 | 24 | M |

| KBS85.500.125 | SZ | 85 | 500 | 1.25 | 3000 | 5.620 | 24 | M |

| KBS85.600.125 | SZ | 85 | 600 | 1.25 | 3000 | 6.430 | 24 | M |

| ZMKBS85.100.100 | DF | 85 | 100 | 1 | 3000 | 1.947 | 24 | M |

| ZMKBS85.150.100 | DF | 85 | 150 | 1 | 3000 | 2.310 | 24 | M |

| ZMKBS85.200.100 | DF | 85 | 200 | 1 | 3000 | 2.607 | 24 | M |

| ZMKBS85.300.100 | DF | 85 | 300 | 1 | 3000 | 3.047 | 24 | M |

| ZMKBS85.400.100 | DF | 85 | 400 | 1 | 3000 | 3.993 | 24 | M |

| ZMKBS85.500.125 | DF | 85 | 500 | 1.25 | 3000 | 6.270 | 24 | M |

| ZMKBS85.600.125 | DF | 85 | 600 | 1.25 | 3000 | 8.503 | 24 | M |