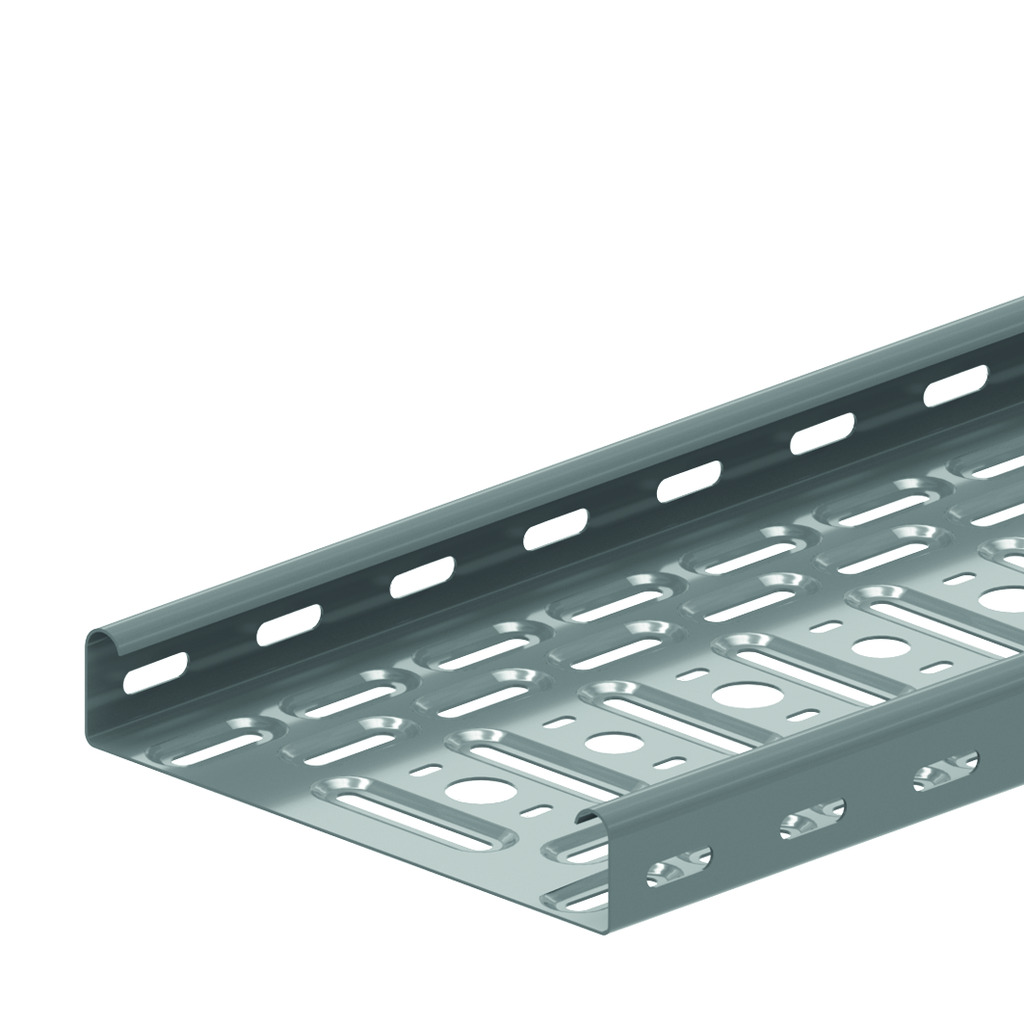

Perforated cable tray - KBS35

Alternative perforation

Return flanges

ETIM: EC000047

Return flanges

ETIM: EC000047

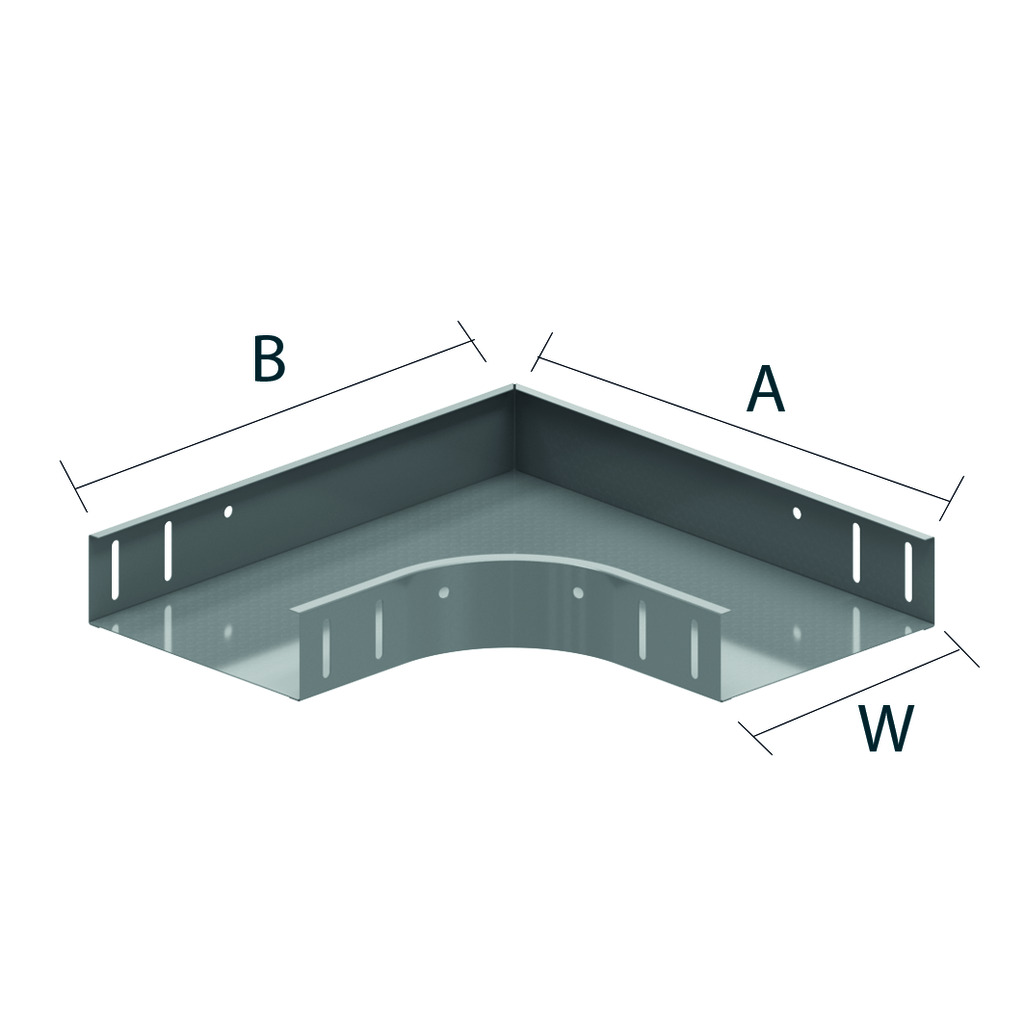

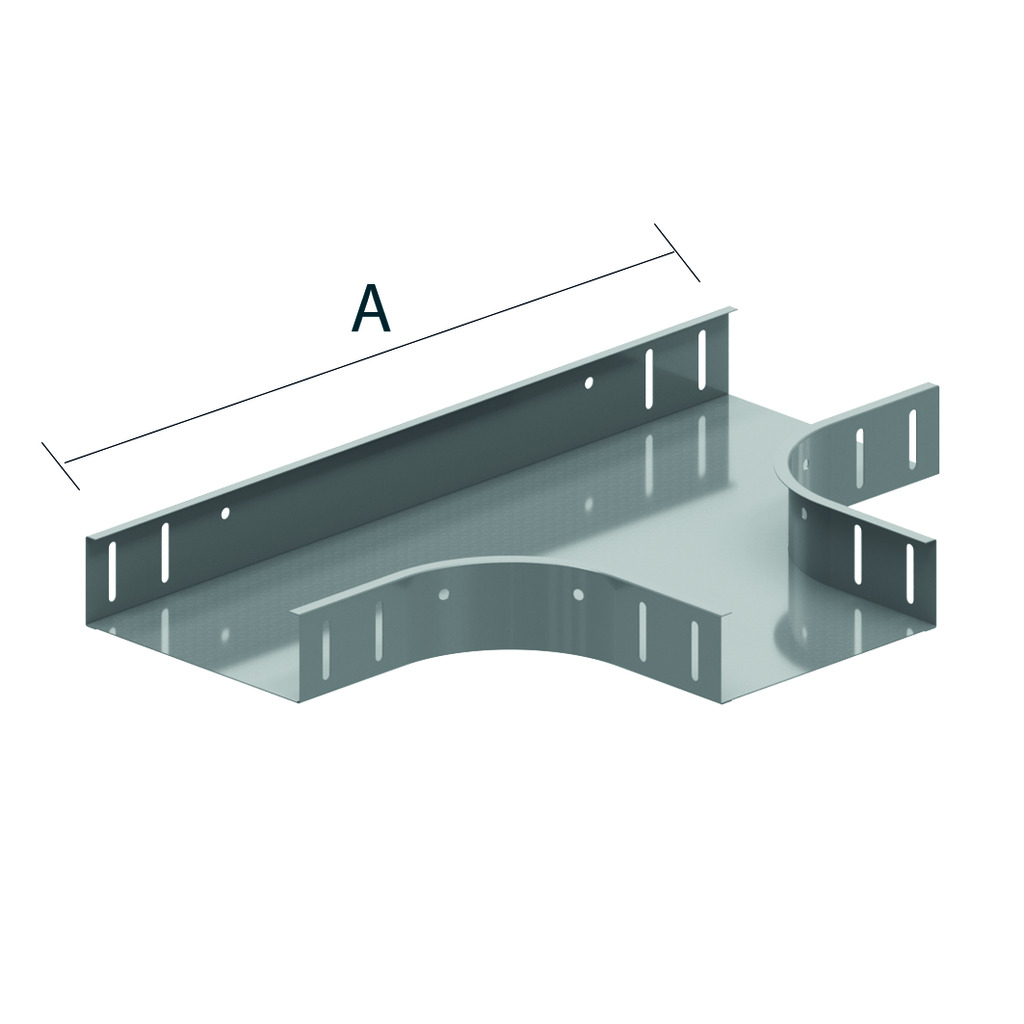

| Reference |

mm |

mm |

mm |

mm |

kg m |

Unit | |

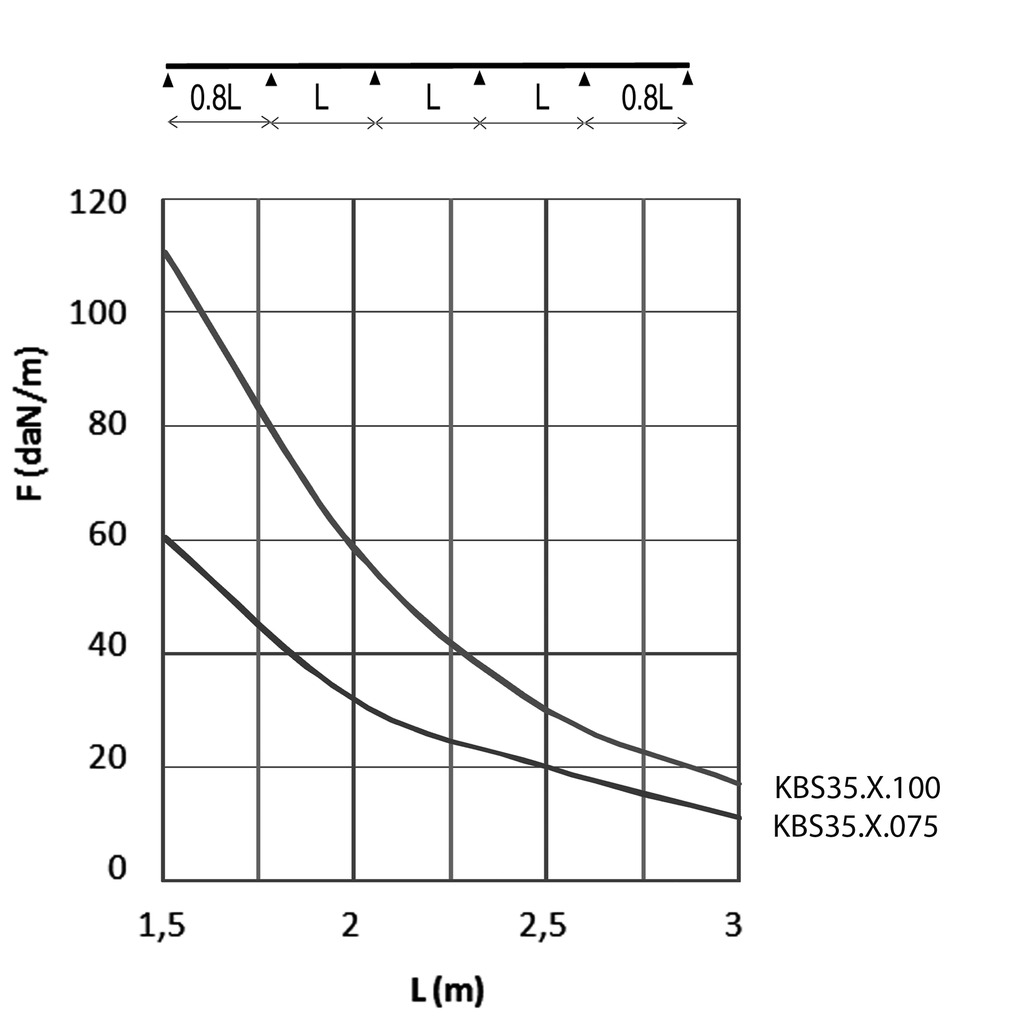

| KBS35.050.075 | 35 | 50 | 0.75 | 3000 | 0.680 | 150 | M |